Most machinery rebuilders are able to handle an incredibly wide variety of machines and mechanisms, and are also able to get the job done according to the timeline required by the customer. Remanufacturing is one of the most basic and well-known machinery rebuilder services. In essence, remanufacturing involves dissembling a machine so that all the individual pieces can be checked, cleaned and when necessary replaced before the machine is put back together in better working order (but still in the same fashion as that of the original manufacturer). Another common practice in machinery rebuilding facilities is retrofitting. Retrofitting installs newer parts into older machinery, giving it greater speed, more precision or other mechanical aspects that improve machine’s capabilities.

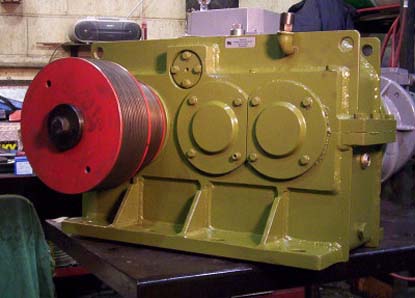

A final major service offered by machinery rebuilders is equipment repair, which basically means that a customer will bring in a machine with a single component that needs to be fixed or replaced to return the machine to its prior efficiency. Some machine repair companies will focus on fixing certain types of machine issues. For example, an automotive job shop focuses on fixing vehicle issues, while other machinery rebuilders may specialize in gearbox repair.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services