Some factors to consider when choosing a machine tool repair company include its experience in the business, the types of machine tools they repair, and the company’s reputation. Read More…

Element Machinery is an engineering and manufacturing company that builds automated equipment primarily in the metals processing industry. For years we have been providing dependable service and products. We strive to have the highest quality products in the industry while continuously improving and expanding.

At Bear Ridge Machine & Fabrication, Inc., we pride ourselves on being trusted machinery rebuilders dedicated to extending the life, efficiency, and performance of industrial equipment. We bring together decades of hands-on experience with advanced machining and fabrication capabilities, allowing us to deliver complete solutions that restore worn or outdated machinery to peak operating condition.

At Carmel Engineering, we take pride in being a trusted partner in machinery rebuilding and precision engineering. With decades of hands-on experience, we have built our reputation on the ability to restore, enhance, and modernize industrial equipment so that it performs at peak efficiency.

More Machine Tool Repair Companies

Machine tools are essential for precision manufacturing, enabling the removal of metal from a workpiece while firmly holding the cutting tools in place. When machine tools break down ("down" machine tool), production halts, capacity is limited, and revenue is lost. This makes machine tool repair an urgent and critical process for manufacturers, machine shops, and industrial operations. Timely repair and maintenance restore malfunctioning or inefficient machines to optimal working order, minimizing costly downtime and maximizing productivity.

But what exactly does machine tool repair involve? Whether you're dealing with CNC equipment, lathes, milling machines, grinders, or manual tools, repair services address failures, restore accuracy, and bring assets back to peak performance. Repairs are performed when an asset breaks, is damaged, or ceases to function as intended. Regular maintenance and professional repair extend the lifespan of machinery, helping you avoid complete breakdowns and the high expenses that come with them.

Machine tool repair services cater to a wide range of sectors, including aerospace, automotive, defense, energy, and general industrial manufacturing. The importance of maintaining consistent machine tool performance cannot be overstated—precision machining relies on the tight tolerances and repeatability only well-maintained equipment can provide. Companies searching for machine tool repair near me or CNC machine repair services are often seeking urgent solutions to restore productivity and keep their operations running smoothly. If you operate a fabrication facility, high-volume CNC shop, or even a small-scale toolroom, investing in comprehensive machine tool repair ensures you remain competitive in today’s demanding markets by minimizing risk of unplanned downtime and maintaining compliance with industry regulations.

Efficient machine tool repair is not only a solution for unexpected failures but also a strategic approach for extending the life of expensive manufacturing equipment and supporting continuous improvement initiatives. As smart manufacturing, digitalization, and Industry 4.0 initiatives become more prevalent, the ability to keep legacy and modern machinery running reliably is more important than ever for operational efficiency and business continuity.

Signs That the Machine Tool Needs Repair

Recognizing early warning signs of machine tool failure is vital for preventing unplanned downtime and expensive repairs. If you’re wondering, "How do I know if my machine tool needs servicing?" watch for these common indicators that often prompt searches for machine tool repair services or CNC repair near me:

- Tool Age: Over time and with frequent use, machine tools naturally wear down. Regular evaluations—ideally every six months by a professional technician—help identify wear and tear before it leads to major issues. Scheduled machine tool inspection and preventive maintenance can alert you to repair or replacement needs in advance, reducing the risk of unexpected failure.

- Strange Noises: Unusual sounds, such as grinding, squealing, or knocking, often signal internal problems like bearing wear, misalignment, or lubrication failure. If your equipment starts making new or louder noises, don’t ignore them—addressing these early can save both the machine and your tooling investment.

- Difficulty of Use: Increased resistance, binding, or erratic operation suggest underlying damage or malfunction. Machines that are hard to operate or produce inconsistent results should be taken out of service and inspected immediately to prevent further harm and ensure operator safety.

- Obvious Buildup: Accumulated debris, rust, coolant residue, or unidentifiable buildup inside or on machine tools can cause clogs, corrosion, and decreased performance. If you notice buildup during routine cleaning or after long-term storage, have a specialist assess the equipment before use.

- Loss of Precision: If your machine tool is producing out-of-tolerance parts or surface finishes are inconsistent, it may be due to worn ball screws, way covers, spindle bearings, or misaligned axes. Loss of repeatability is a key sign that repair or calibration is needed to restore manufacturing quality.

- Excessive Vibration: Vibration beyond normal operational levels can indicate misalignment, unbalanced rotating assemblies, or foundation issues. Left unchecked, vibration can accelerate wear and damage to sensitive machine tool components.

- Increased Cycle Times: If production runs take longer than usual or your CNC program is pausing unpredictably, it may indicate servo drive issues, control faults, or lubrication problems. These delays can impact delivery commitments and profitability.

- Alarm Codes and Error Messages: Modern CNC machines display error codes when faults occur. Frequent alarms should not be dismissed—consulting a technician for diagnostic troubleshooting can prevent further escalation.

Are you searching for: Why is my CNC machine making odd noises? or When should I schedule machine tool maintenance? Early detection of these warning signs is crucial to maximizing equipment uptime and minimizing repair costs. If you’re experiencing excessive vibration, loss of accuracy, or inconsistent part finishes, it could indicate underlying spindle problems, axis misalignment, or worn mechanical assemblies. Prompt diagnosis by a certified machine tool technician can prevent further damage and reduce overall repair expenses.

Levels of Repair: Partial vs. Complete Machine Tool Failure

The extent of machine tool repair required depends on the degree of asset failure. Understanding the difference between partial and complete failure helps facilities prioritize repairs and plan maintenance schedules. Here’s how to evaluate equipment condition:

- Partial Failure: The equipment still operates, but at reduced efficiency, capacity, or safety. Warning signs might include inconsistent output, minor leaks, vibration, or decreased precision. Addressing partial failures with prompt corrective maintenance or troubleshooting can restore full functionality and prevent escalation to total breakdown.

- Complete Failure: The asset is entirely nonfunctional, often due to neglected warning signs or skipped preventive maintenance. Repairing from total failure is more time-consuming and costly, involving extensive diagnostics, parts replacement, re-alignment, or even machine rebuilding. Complete failure can also introduce safety hazards and abruptly halt production lines.

Looking to compare machine tool repair vs. replacement? Consider the cost, downtime, and expected lifespan after each option. Minor issues can often be fixed economically, while major structural or electronic failures may warrant a replacement or full refurbishment. For high-value assets like CNC machining centers or multi-axis lathes, a thorough cost-benefit analysis is essential before making a decision. If you’re asking, "Should I repair or replace my CNC machine?" evaluate the age, condition, and availability of critical spare parts before moving forward. Consider the impact on production schedules, future maintenance requirements, and the compatibility of your equipment with evolving technology standards.

Comprehensive Machine Tool Maintenance: Preventive and Predictive Strategies

Routine machine tool maintenance is essential to ensure long service life, safety, and process accuracy. There are two main approaches:

- Preventive Maintenance: Scheduled maintenance tasks—including lubrication, calibration, inspection, and part replacement—reduce the risk of unexpected breakdowns. Preventive care addresses known wear points and is ideal for high-value assets like CNC machines, lathes, and grinders.

- Predictive Maintenance: Advanced monitoring tools and sensors track real-time machine performance, alerting technicians to developing issues before failure occurs. Vibration analysis, thermography, and oil analysis help optimize maintenance schedules and reduce unnecessary downtime.

If you’re asking, "What’s the best way to extend CNC machine tool life?" or "How often should I service my lathe or milling machine?"—the answer is a tailored mix of preventive and predictive maintenance, guided by equipment age, usage, and manufacturer recommendations. Leveraging predictive analytics and condition monitoring not only helps in early fault detection but also supports lean manufacturing and overall equipment effectiveness (OEE) objectives. As a result, you can ensure maximum machine uptime, reduce total cost of ownership, and maintain high standards of product quality.

Incorporating a robust maintenance program not only helps avoid emergency breakdowns but also ensures consistent part quality and process repeatability. Many manufacturers implement Computerized Maintenance Management Systems (CMMS) to track service intervals and automate reminders for scheduled tasks. Utilizing original equipment manufacturer (OEM) guidelines for maintenance enhances the longevity and reliability of both new and legacy machine tools.

Preventive and predictive maintenance programs are especially important for industries with demanding quality standards, such as aerospace, medical device manufacturing, and automotive production. These sectors require strict adherence to ISO and AS standards, mandating regular documentation of machine tool servicing and calibration. By aligning your maintenance strategy with these requirements, you protect both your operational reputation and your ability to win critical contracts.

Importance of Machine Tool Repair and Maintenance

- Prolongs Equipment Lifespan: Regular repair and maintenance keep CNC machines, manual lathes, mills, and other tools operating at peak performance for years longer than neglected equipment.

- Detects Hidden Defects: Proactive inspections catch subtle issues—such as dings, cracks, spindle misalignment, or electronic faults—before they cause catastrophic failure.

- Reduces Production Delays: Well-maintained machines ensure consistent output, minimize downtime, and help meet tight production deadlines.

- Enhances Workplace Safety: Properly serviced machine tools reduce the risk of accidents and injuries caused by unexpected malfunctions.

- Maximizes Return on Investment: Protect your capital investments by extending the usable life of expensive machinery and avoiding the high cost of premature replacement.

- Ensures Regulatory Compliance: Many industries must adhere to strict quality and safety standards (such as ISO 9001 or AS9100). Regular maintenance and certified repairs help ensure compliance during audits and inspections.

- Supports Lean Manufacturing: Consistent machine tool performance reduces waste, improves first-pass yield, and enhances production flow, directly supporting lean manufacturing goals and continuous improvement initiatives.

Curious about how machine tool repair can improve your bottom line? Explore cost-benefit analyses or contact a machine tool service provider for a tailored maintenance plan. Ask yourself: What are the long-term savings of a proactive maintenance strategy? or How can I reduce unplanned downtime in my production facility?

Advantages of Machine Tool Repair Services

- No Extensive Planning Needed: Simple repairs can often be performed quickly, with minimal disruption to ongoing operations.

- Lower Short-Term Costs: Addressing issues as they arise can be less expensive than comprehensive overhauls, especially for minor faults.

- Straightforward Process: Basic troubleshooting and targeted repairs require less diagnostic equipment and downtime compared to full preventive maintenance routines.

- Fast Turnaround: Many common repairs—such as replacing bearings, belts, or electrical components—can be completed quickly, getting your machines back online faster.

- Extends Machine Tool Life: Timely repairs prevent small issues from escalating, supporting longer operational life without major overhauls.

- On-Site and Emergency Support: Many repair providers offer on-site repairs, 24/7 emergency service, and mobile machining to restore production quickly and reduce transportation costs.

For organizations prioritizing operational agility, rapid-response machine tool repair services are invaluable. Many repair providers offer same-day or next-day service for critical breakdowns, minimizing lost production time. If you’re searching for emergency machine tool repair services or mobile machining repair, be sure to evaluate local providers based on their response times and spare parts inventory. Quick access to qualified technicians and a well-stocked parts inventory can make the difference between a minor interruption and a major production crisis.

Disadvantages of Machine Tool Repair

- Unaddressed Faults Can Escalate: Focusing only on repairs without a maintenance plan may allow underlying issues to worsen, risking greater damage.

- Production Interruptions: Emergency repairs often require unscheduled downtime, reducing productivity and potentially delaying order fulfillment.

- Higher Labor Costs: Frequent unplanned repairs can increase labor expenses and overtime, especially during critical production periods.

- Potential System Failure: Ignoring regular maintenance can create unsafe working environments and lead to expensive, system-wide failures.

- Lack of Predictability: Relying on reactive repairs rather than systematic maintenance increases uncertainty in scheduling and budgeting, impacting both short-term and long-term operational planning.

- Risk of Repeat Failures: Fixing symptoms rather than root causes can lead to recurring problems. A comprehensive diagnostic approach is needed to resolve underlying machine tool issues for sustained reliability.

If you’re comparing machine tool repair vs. preventive maintenance, consider the operational risks and hidden costs associated with reactive strategies. A comprehensive maintenance plan may require a larger upfront investment, but typically results in lower total cost of ownership and greater equipment reliability over time. Weigh the advantages of scheduled downtime against the unpredictability and higher expenses of emergency repairs, especially for high-throughput production environments.

Key Applications for Machine Tool Repair Services

Machine tool repair is vital across industries and applications. From precision manufacturing and automotive part production to aerospace machining and metal fabrication, properly maintained equipment is crucial for quality output. Typical use cases include:

- CNC Machine Tool Repair: Includes spindle repair, axis alignment, control system troubleshooting, and servo drive replacement to restore accuracy in automated production environments.

- Manual Machine Tool Refurbishment: Restores lathes, drill presses, and mills to original specifications, improving tolerances and operational safety.

- Industrial Grinder and Surface Finisher Repair: Precision grinding tools require regular maintenance for flatness, surface finish, and bearing replacement.

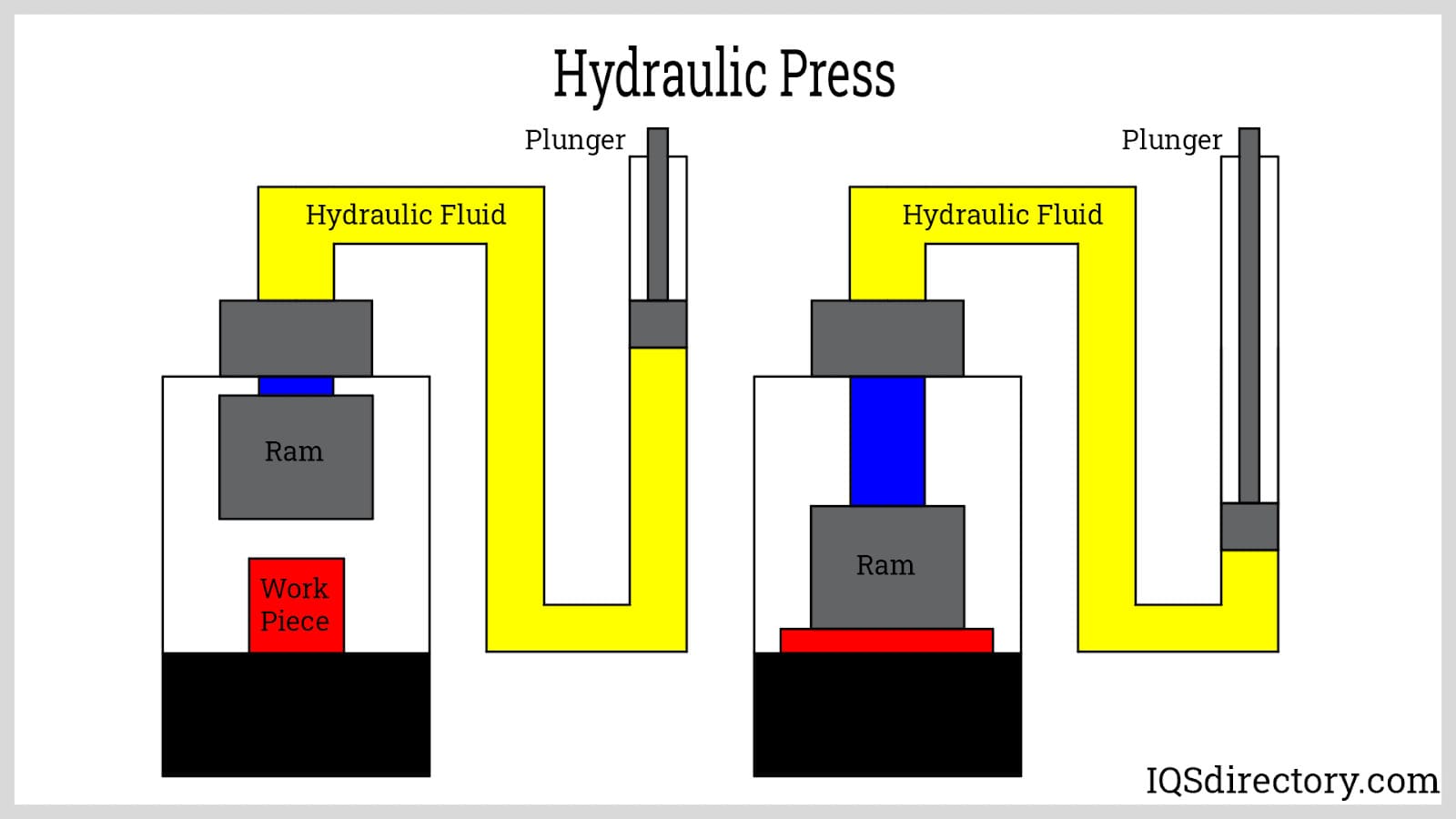

- Hydraulic and Pneumatic System Repair: Many machine tools use hydraulic or pneumatic components for clamping, movement, or tool changes. Seals, valves, and hoses often require replacement.

- Electrical and Electronic Repair: Replacing sensors, PLCs, wiring, and control panels is essential for reliable, automated manufacturing workflows.

- Laser and EDM Machine Repairs: Specialized equipment such as laser cutters and electrical discharge machines (EDMs) have unique servicing needs, including optics calibration and power supply troubleshooting.

- Robotics and Automation Integration: As smart manufacturing and Industry 4.0 advances, integrating robotics and automation into existing machine tools often requires specialized repair and retrofit services.

- Specialty Machine Tool Repair: Equipment used for additive manufacturing, Swiss turning, or multi-axis machining may require unique expertise and specialized parts, highlighting the need for an experienced service provider.

Not sure which services you need? Browse: What types of machine tool repair are available? or How do I find a qualified machine tool repair technician? You can also refine your search by including your equipment brand or model, such as "Haas CNC repair services" or "Bridgeport mill repair near me". Consider whether your facility requires on-site field service, in-shop machine rebuilding, or remote diagnostics based on the complexity of your operations and the type of machine tools in use.

Factors to Consider When Choosing a Machine Tool Repair Service

Selecting the right machine tool repair company can make all the difference in equipment reliability, turnaround time, and long-term value. Key decision factors include:

- Experience and Certification: Look for providers with certified technicians experienced in your specific equipment brands (Fadal, Mazak, Haas, Okuma, Bridgeport, etc.).

- Range of Services: The best repair companies offer both field service (on-site repair) and in-shop rebuilding, as well as preventive maintenance contracts and emergency breakdown support.

- Response Time: Fast response minimizes downtime. Ask about 24/7 emergency service, local coverage, and average repair turnaround.

- Parts Availability: Access to OEM and aftermarket parts ensures quick repairs and lasting results. Confirm that your repair partner stocks or sources critical components.

- Warranty and Support: Reputable repair companies back their work with service warranties and ongoing technical support, giving you confidence in repair quality.

- Customer Reviews and Case Studies: Look for testimonials, references, and case studies that demonstrate successful repairs and satisfied clients in your industry.

- Pricing Transparency: Ensure the company provides clear estimates, labor rates, and warranty terms for all repair services. Avoid vendors that are vague about costs or timelines.

- Geographic Reach: If your operation spans multiple locations or states, consider working with a national or regional repair provider capable of supporting your entire footprint.

- Technological Expertise: As CNC controls, automation, and robotics become more sophisticated, select a repair partner with up-to-date knowledge of the latest controls, software, and integration best practices.

Wondering "How do I compare machine tool repair service providers?" or "What questions should I ask a machine tool repair contractor?" Consider using a checklist or request-for-quote (RFQ) form to evaluate multiple suppliers side by side. Common RFQ questions include: What is your average response time for emergency repairs? Can you provide references for similar projects? Do you offer on-site diagnostics and remote support?

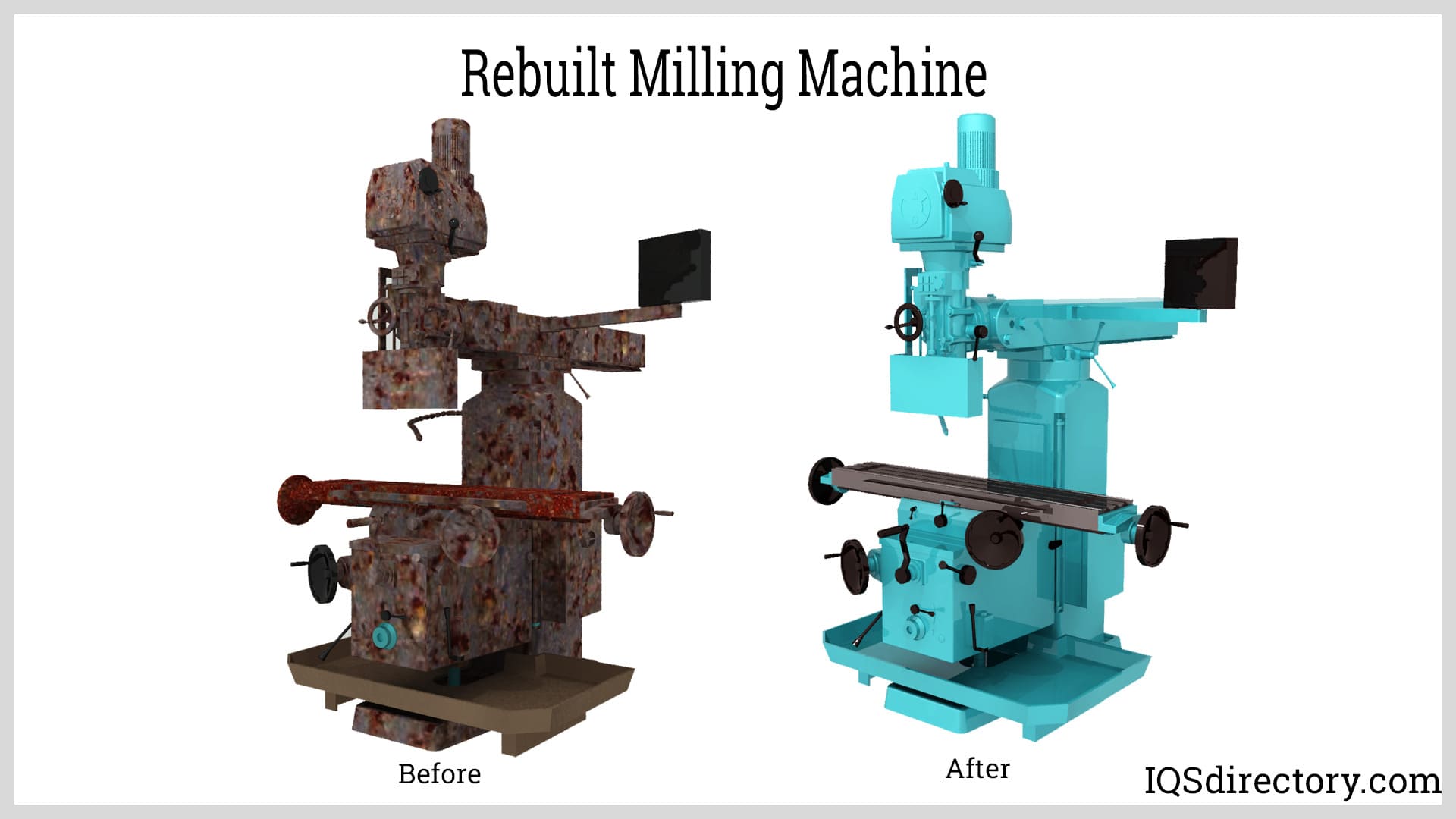

Machine Tool Rebuilding and Retrofit Services

When repairs alone are not enough, machine tool rebuilding or retrofit services can breathe new life into legacy equipment. Rebuilding involves stripping machines down to their base, replacing worn parts, re-machining surfaces, and upgrading controls or drive systems. Retrofitting adds modern CNC controls, automation, or safety features to older machines, improving productivity and compliance with current standards.

- Advantages of Rebuilding: Cost-effective compared to new machine purchase, extends useful life, preserves custom tooling setups, and minimizes training needs.

- Retrofit Benefits: Access to advanced controls, improved part quality, increased throughput, and integration with digital manufacturing systems (Industry 4.0).

- Environmental Impact: Rebuilding and retrofitting reduce waste by extending the usable life of existing equipment, aligning with sustainability and circular economy goals.

- Customization: Modernization projects can be tailored to your unique production requirements, such as adding automation, robotics, or improved safety features.

- Reduced Lead Times: Rebuilding or retrofitting existing machines can be completed faster than waiting for new equipment delivery and installation, minimizing disruptions to production schedules.

Researching Is it better to rebuild or replace a machine tool? or Can old machines be upgraded for modern production?? Consult with a reputable machine tool rebuilder to explore your options and calculate long-term ROI. Many companies offer free initial consultations and site assessments to evaluate the condition and upgrade potential of your equipment. Machine tool retrofit projects can also qualify for tax incentives or energy efficiency grants, further improving return on investment for forward-thinking manufacturers.

Cost Considerations: Machine Tool Repair, Maintenance, and Replacement

Budgeting for machine tool repair and maintenance is a critical aspect of operational planning. Costs vary depending on the nature of the repair, the type of equipment, and the urgency of the service required. Here are some key factors influencing cost:

- Type of Repair: Basic tasks like replacing belts, bearings, or sensors are generally less expensive than complex overhauls such as spindle rebuilds or control retrofits.

- Parts and Labor: OEM parts may carry a premium, but ensure long-term reliability. Labor rates can vary depending on technician experience and geographic location.

- Downtime Impact: The cost of lost production during repairs can outweigh the direct expense of the repair itself. Investing in preventive maintenance reduces unexpected downtime and associated costs.

- Warranty Coverage: Some manufacturers and third-party service providers offer extended warranties on repairs, which can provide peace of mind and help control future expenses.

- Age and Condition of Equipment: Older machines may require more frequent repairs or complete overhauls. Sometimes, investing in a new or refurbished machine is more cost-effective over the long term.

- Complexity of Machine Tool: Multi-axis CNC machining centers, EDMs, and automated production lines often require highly specialized repair services, affecting both time and cost estimates.

- Geographic Location: Remote facilities may incur additional travel fees for technicians or increased shipping costs for critical spare parts, impacting the total project cost.

If you’re asking, "How much does it cost to repair a CNC machine?" or "What is the ROI of machine tool rebuilding?", request detailed quotes from several service providers and compare based on total value, not just initial price. Consider warranty terms, parts quality, and post-repair support as part of your overall assessment. For ongoing operations, factor in the savings from reduced downtime, increased machine utilization, and improved product quality when calculating the total cost of ownership of your manufacturing equipment.

Conclusion: Maximizing Value from Your Machine Tools

Machine tools are the backbone of modern manufacturing, enabling the production of precision components for industries ranging from automotive and aerospace to energy and electronics. They rely on four fundamental elements: a power source for controlled motion, secure work holding, precise tool orientation, and robust regulation of these systems. When any element fails, machine tool repair is required to restore full function, accuracy, and safety.

Proactive maintenance—combined with skilled repair and, when needed, machine tool rebuilding—delivers the best value for manufacturers. Investing in qualified service providers minimizes downtime, extends machine life, and ensures consistent product quality. Whether you operate a high-volume CNC job shop or a small manual machine shop, prioritizing machine tool repair and maintenance is essential for business success. As manufacturing technology evolves, regularly evaluating your maintenance strategy and repair partners guarantees that your assets remain competitive and your production lines resilient against unplanned interruptions.

Choosing the Proper Machine Tool Repair Company

To ensure the best outcome when sourcing machine tool repair services, always compare at least 5 suppliers. Use directories or supplier lists to research each machine tool repair company—review their business profiles, experience, and capabilities. Most reputable providers offer website previews, detailed service descriptions, and direct contact forms to request quotes or more information.

Want to streamline your search? Use an RFQ tool to message multiple repair companies with your requirements, then compare responses by price, turnaround, and service scope. For complex or high-value repairs, ask for references or case studies to evaluate past performance. Don't hesitate to ask: Which machine tool repair company offers the fastest response in my area? or What are the best-rated machine tool repair services near me? When evaluating potential partners, consider their ability to support both legacy and new-generation machine tools, their investment in ongoing technician training, and their commitment to customer service and transparency.

Ready to protect your investment, reduce downtime, and boost productivity? Contact a certified machine tool repair specialist today for a comprehensive evaluation of your equipment—and discover how a proactive repair and maintenance strategy can transform your operations.

Frequently Asked Questions About Machine Tool Repair

- What is the average turnaround time for machine tool repairs? Most standard repairs can be completed within 1–3 business days, but complex overhauls may take longer depending on parts availability and workload.

- Can I perform some machine tool maintenance in-house? Yes, many routine tasks—such as cleaning, lubrication, and visual inspection—can be handled by trained staff. However, precision repairs and diagnostics should be left to certified professionals to maintain warranty coverage and equipment safety.

- How do I choose between repair, rebuild, and replacement? Consider the age, value, and condition of your machine. If the cost of repair approaches 50% of the replacement value, a rebuild or replacement may be the better choice. Consult with an expert for a detailed assessment.

- What types of machine tool repair services are available? Most providers offer mechanical and electrical repairs, spindle rebuilds, control retrofits, on-site troubleshooting, and preventive maintenance contracts for both CNC and manual equipment.

- How can I improve the longevity and accuracy of my machine tools? Implement a comprehensive maintenance schedule, use high-quality lubricants and replacement parts, and work with certified service providers for diagnostics and calibration.

- Are there industry standards for machine tool repair? Yes, many sectors follow ISO, AS, and OEM-specific standards for repair, calibration, and documentation. Working with certified repair companies helps ensure compliance and traceability for quality audits.

- What should I look for in a repair warranty? Seek warranties that cover both parts and labor, specify turnaround times for warranty service, and offer clear terms for both in-shop and field repairs.

- Can machine tool repair providers help with machine relocation or installation? Many full-service companies offer relocation, installation, and start-up support, including precision leveling, alignment, and calibration services to ensure equipment operates correctly from day one.

Still have questions? Search: Best practices for CNC machine tool maintenance, Signs you need machine tool repair, or How to find certified machine tool service providers for more insights—or reach out to a local specialist for personalized advice. The right knowledge and service partnership can help your manufacturing operation thrive, no matter how complex your machine tool requirements may be.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services