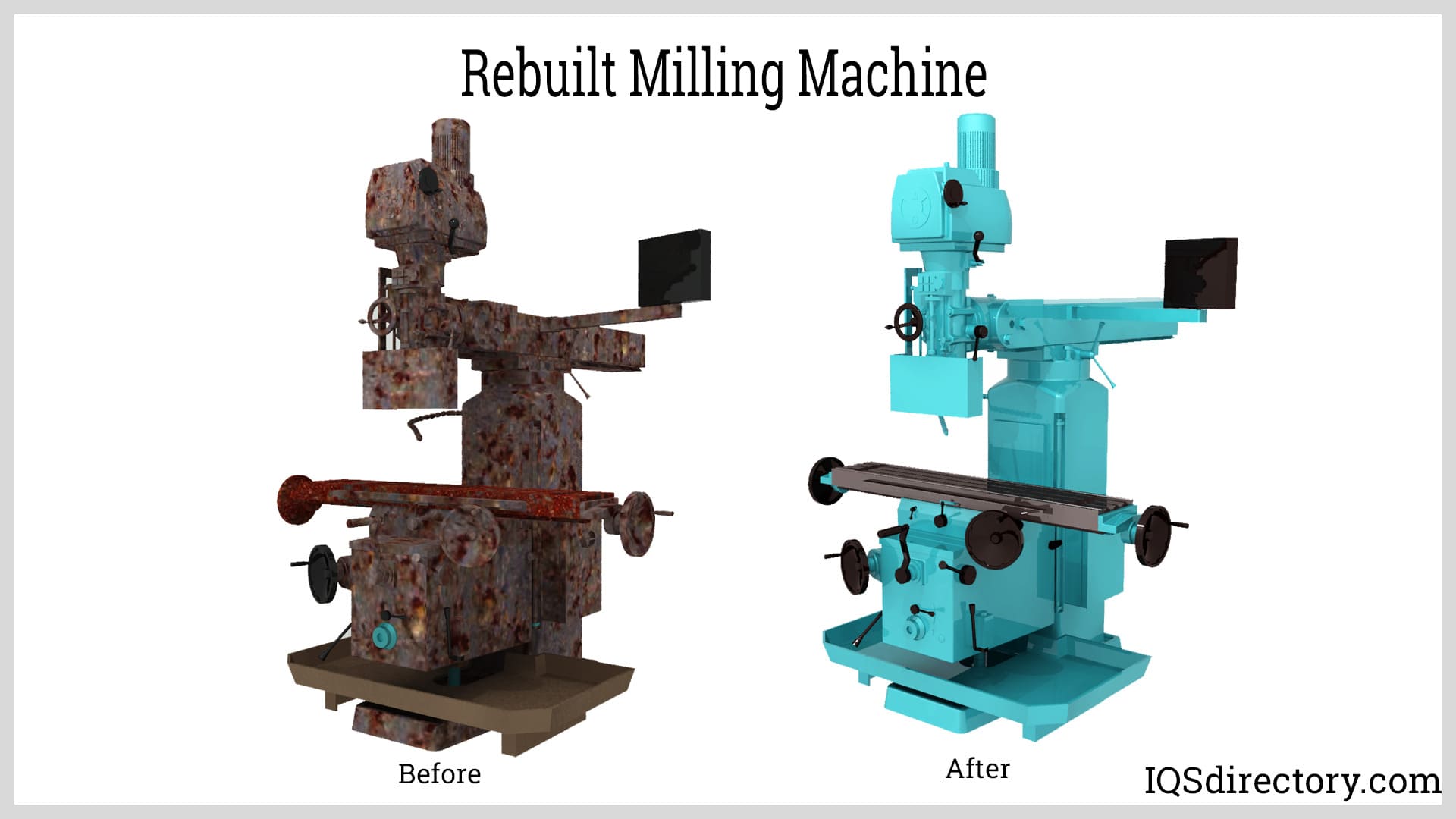

Machine rebuilding refers to the process of restoring and improving the performance, functionality, and reliability of industrial machines, equipment, or machinery that have become worn out, outdated, or inefficient. This typically involves a thorough inspection, disassembly, repair, and replacement of components, as well as upgrading or modernizing certain parts to bring the machine up to current standards and specifications. Read More…

Element Machinery is an engineering and manufacturing company that builds automated equipment primarily in the metals processing industry. For years we have been providing dependable service and products. We strive to have the highest quality products in the industry while continuously improving and expanding.

At Bear Ridge Machine & Fabrication, Inc., we pride ourselves on being trusted machinery rebuilders dedicated to extending the life, efficiency, and performance of industrial equipment. We bring together decades of hands-on experience with advanced machining and fabrication capabilities, allowing us to deliver complete solutions that restore worn or outdated machinery to peak operating condition.

At Carmel Engineering, we take pride in being a trusted partner in machinery rebuilding and precision engineering. With decades of hands-on experience, we have built our reputation on the ability to restore, enhance, and modernize industrial equipment so that it performs at peak efficiency.

More Machine Rebuilding Companies

Machine rebuilding aims to extend the useful life of equipment, reduce maintenance costs, enhance productivity, and ensure safety and compliance with regulations.

Industries That Use Machine Rebuilding

Machine rebuilding is common in several industries where heavy machinery and equipment play a crucial role in production processes. Here are some industries that often utilize machine rebuilding:

Manufacturing: Machine rebuilders are often employed by manufacturers to refurbish and upgrade production machinery, such as CNC machines, presses, and injection molding machines.

Automotive: Automotive manufacturers and suppliers utilize machine rebuilders to refurbish production lines, including robots, conveyors, and machining equipment.

Aerospace: Aerospace companies require machine rebuilders to maintain and improve precision machinery used in aircraft manufacturing, such as CNC mills and lathes.

Mining and Quarrying: In the mining industry, heavy-duty equipment like excavators, loaders, and crushers benefit from rebuilds to maximize their lifespan and efficiency.

Oil and Gas: Machine rebuilders are used to overhaul drilling rigs, pumps, and other equipment used in the oil and gas extraction and processing industry.

Agriculture: Farmers and agricultural businesses may seek machine rebuilders to refurbish and upgrade tractors, combine harvesters, and other farm equipment.

Food Processing: Food processing plants rely on machinery for various processes, and machine rebuilders can help improve the performance and compliance of these machines.

Paper and Pulp: The paper and pulp industry often refurbishes and upgrades machinery like paper machines and pulping equipment to increase productivity and quality.

Packaging: Packaging companies use machine rebuilders to maintain and enhance the efficiency of packaging machines, including fillers, labelers, and cartoners.

Printing and Graphics: Print shops and companies involved in graphic production may refurbish and upgrade printing presses and bindery equipment through machine rebuilding services.

Textiles: The textile industry utilizes machine rebuilders to maintain and improve textile manufacturing equipment like looms, spinning machines, and dyeing machines.

Energy Generation: Power plants, including nuclear, fossil fuel, and renewable energy facilities, use machine rebuilders for the maintenance and repair of turbines, generators, and associated equipment.

Construction: Construction equipment such as bulldozers, excavators, and cranes can benefit from machine rebuilding to extend their operational life.

Rail and Transportation: Rail companies may use machine rebuilders to refurbish locomotives and rolling stock, while transportation companies maintain buses, trams, and other vehicles.

Metalworking: Metalworking facilities rely on machine rebuilders to upgrade and enhance metal fabrication and machining equipment.

Plastics and Rubber: The plastics and rubber industry can refurbish injection molding machines, extruders, and other equipment through machine rebuilding services.

Chemical and Pharmaceutical: Chemical and pharmaceutical companies may seek machine rebuilders to maintain and improve processing equipment, reactors, and mixers.

Woodworking: Manufacturers of furniture, cabinetry, and woodworking products can benefit from machine rebuilding for their woodworking machinery.

Water and Wastewater Treatment: Utilities and municipalities use machine rebuilders to maintain and optimize pumps, filters, and other equipment used in water and wastewater treatment.

Electronics Manufacturing: Electronics manufacturers may refurbish and upgrade production equipment like pick-and-place machines and soldering equipment through machine rebuilding services.

How to Find the Right Machine Rebuilding Company

When choosing machine rebuilding services from a machine rebuilding company, it is important to compare at least 4 or 5 companies using our list of machine rebuilding companies. Each machine rebuilding company has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each machine rebuilding company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple machine rebuilding companies with the same quote.

Finding the right machine rebuilding company for your industry is crucial to ensure that your equipment is restored to its optimal condition and performs efficiently. Here's a step-by-step guide to help you identify and select the right machine rebuilding company:

Define Your Requirements: Start by clearly defining your needs and requirements. What type of machinery do you need to be rebuilt? What are the specific problems or issues you're facing with the equipment? Establish your budget constraints and timelines as well.

Check Qualifications and Credentials: Assess the qualifications and credentials of the potential rebuilders. How long have they been in business, and how many similar projects have they completed? Do they have expertise in your specific type of machinery or equipment? Are they certified by industry organizations or manufacturers?

Review Past Projects: Ask the rebuilder for references or case studies of previous machine rebuilding projects they've completed. This will give you an idea of their capabilities and the quality of their work. Contact these references to inquire about their experiences.

Visit the Facilities: If possible, visit the rebuilder's facilities. This will allow you to assess their equipment, resources, and overall capabilities. A well-equipped facility is essential for quality rebuilding work.

Request Detailed Proposals: Contact the potential rebuilders and request detailed proposals. These proposals should outline the scope of work, timelines, costs, and any warranties or guarantees offered. Compare the proposals to ensure they align with your requirements.

Evaluate Communication and Customer Service: Pay attention to how responsive and communicative the rebuilder is during the proposal phase. Effective communication is crucial throughout the rebuilding process. Ask about their customer service policies and procedures.

Check for Insurance and Safety Measures: Ensure that the rebuilder has adequate insurance coverage and follows safety protocols. This is important to protect your interests and maintain a safe working environment.

Consider Location and Logistics: Evaluate the rebuilder's location in relation to your facility. A closer proximity can reduce transportation costs and downtime during the rebuilding process. Additionally, consider the logistics of transporting your machinery to and from their facility.

Evaluate Pricing: While cost is a factor, it should not be the sole determinant. Choose a rebuilder that offers a fair price while also meeting your quality and timeline requirements.

Finalize the Agreement: Once you've conducted a thorough evaluation and selected a rebuilder that meets your criteria, finalize the agreement. Ensure that all terms and expectations are clearly outlined in a written contract.

Monitor Progress: Stay involved during the rebuilding process and monitor progress to ensure that the work is proceeding as agreed upon.

By following these steps and conducting due diligence, you can find the right machine rebuilding company for your industry, ensuring that your equipment is restored to peak performance and longevity.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

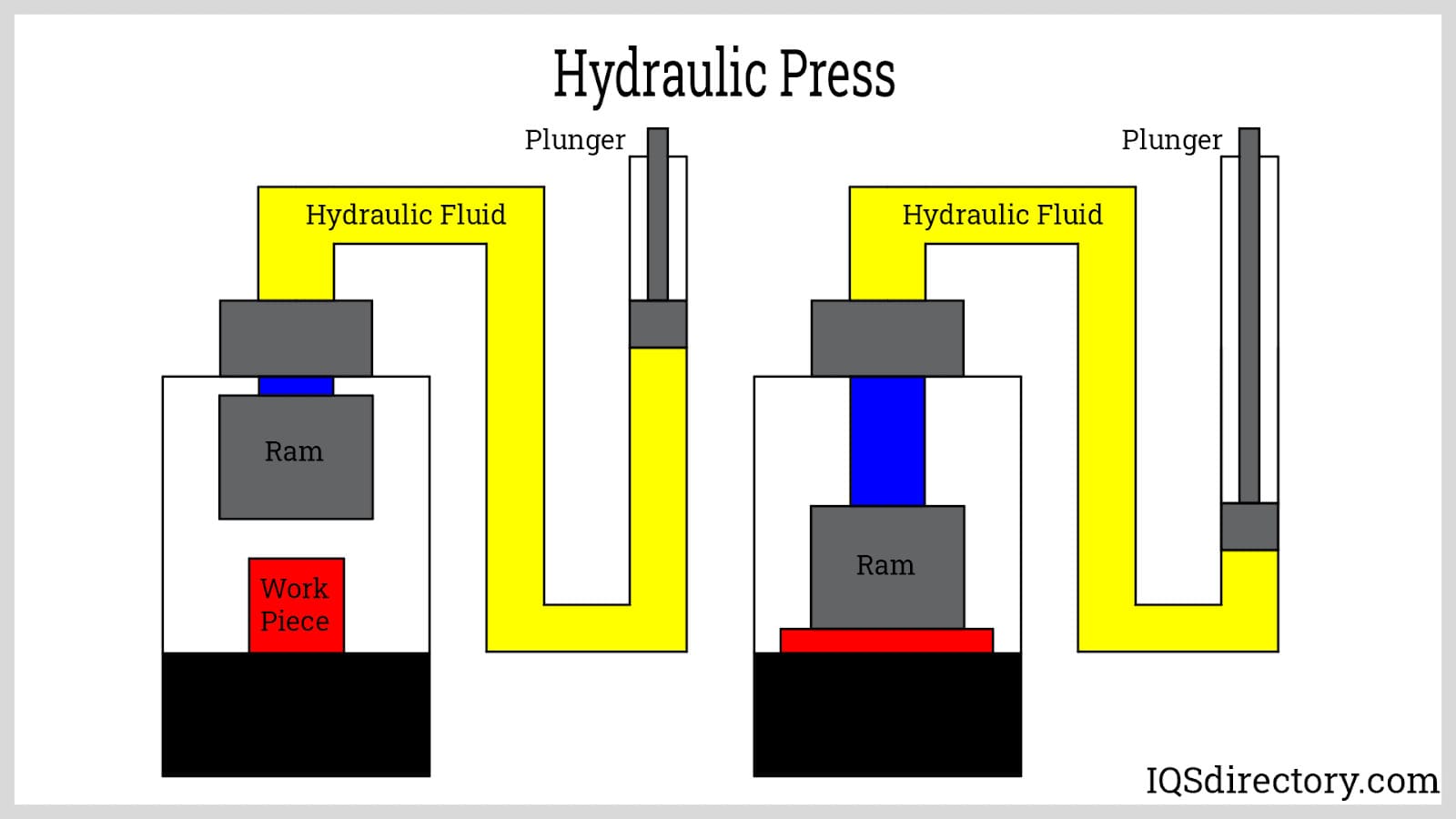

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services