More Machinery Rebuilding Companies

Machinery rebuilders are specialized professionals who typically operate out of advanced machine shops equipped with state-of-the-art tools, diagnostic equipment, and precision instruments. These experts offer a comprehensive suite of services, ranging from equipment repair and preventative maintenance to complete machinery rebuilding, remanufacturing, and retrofitting. Their work is essential for the ongoing functionality and optimization of industrial equipment and machine tools.

If you’re searching for machinery rebuilding services or need to find a trustworthy machine rebuilder near you, it’s important to understand the scope of solutions available. Machinery rebuilders serve a vast range of industries—including automotive, aerospace, computer electronics, manufacturing, textiles, green energy, food and beverage, pharmaceutical, and printing—addressing the unique needs and technical requirements of each sector.

Whether you require heavy equipment repair for industrial manufacturing or precision component refurbishment for electronics, experienced machinery rebuilders have the skills to repair, overhaul, upgrade, and optimize a diverse array of components, machines, and systems. This includes both large-scale industrial machinery and delicate small electronic parts.

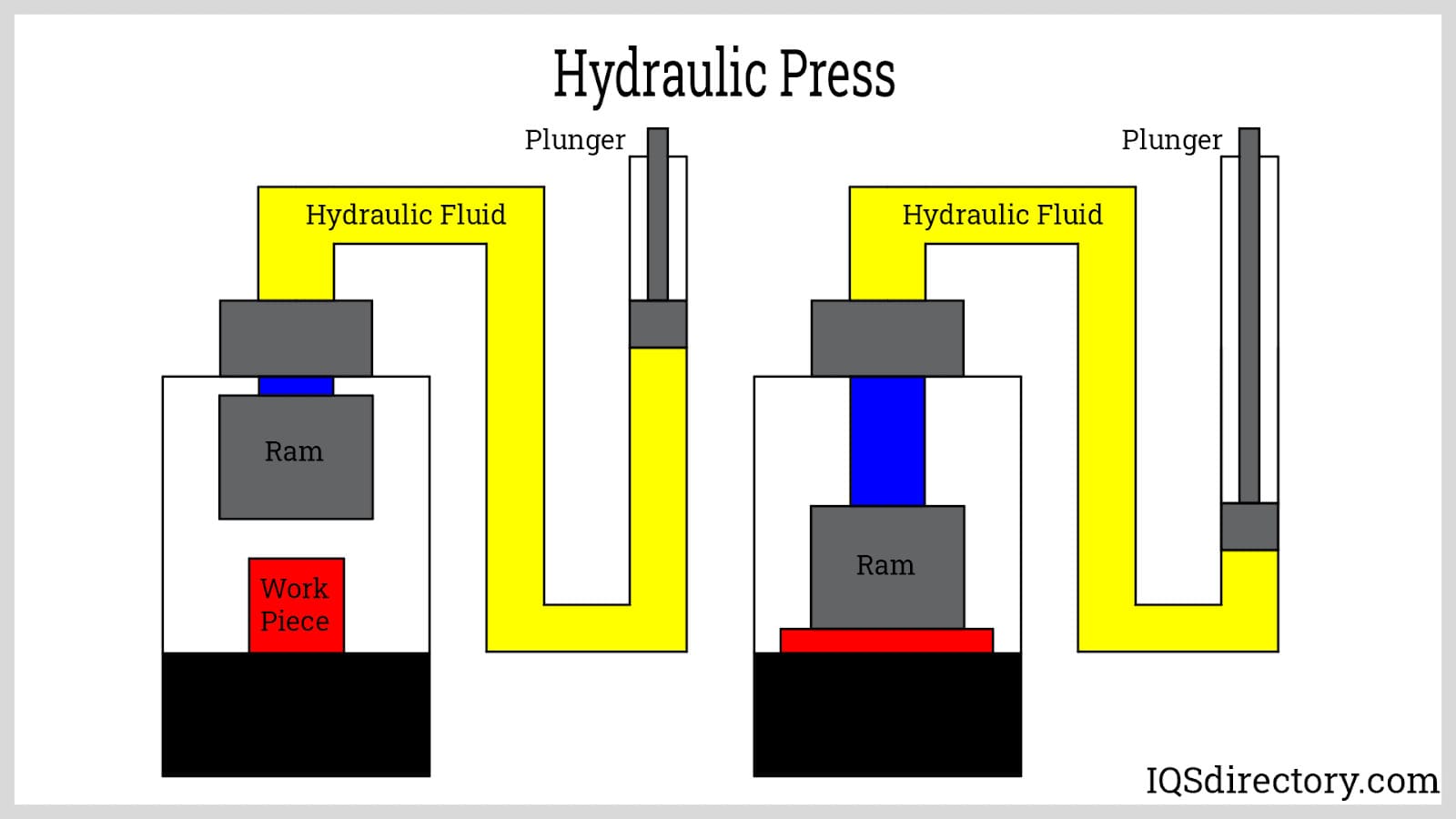

In the industrial manufacturing sector, for example, machine rebuilders routinely repair and rebuild crucial equipment such as presses, pumps, gearboxes, spindles, ball screws, lathes, and a variety of machine tools. These services are critical for minimizing downtime, extending equipment life, and ensuring compliance with industry standards.

Press repair and rebuilding is vital for equipment that applies force or pressure to materials, such as C-frame presses, hydraulic presses, mechanical presses, printing presses, and stamping presses. These machines are subject to high operational stresses and require regular maintenance and expert press repair to maintain safety and productivity.

Pump repair services address all major pump types, including centrifugal, hydraulic, metering, and vacuum pumps. Any machinery designed to transfer, compress, or lift fluids can benefit from professional pump rebuilding or remanufacturing, which restores performance, improves energy efficiency, and reduces costly breakdowns.

Tool repair, machine tool repair, and rebuild services are essential for maintaining devices used in both automated and manual operations. This category covers everything from power machine tools and pressure sensors to precision measurement instruments, ensuring accuracy and reliability in production environments.

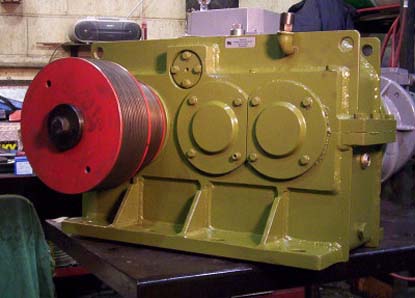

Gearbox repair is a highly specialized service encompassing various gearbox configurations, such as spur, helical, bevel, and planetary gearboxes. These components are vital for power transmission in industries like aerospace, automotive manufacturing, robotics, and renewable energy. Gearbox repair services include fault diagnosis, part replacement, reassembly, and dynamic balance testing to ensure optimal operation and prevent unexpected failures.

Spindle repair and rebuilding, though less frequent, are indispensable in sectors like textiles and high-precision machining. Spindles are used to spin, twist, or rotate components, and their precision is crucial for product quality. Services include bearing replacement, dynamic balancing, vibration analysis, and regrinding to restore original performance.

Ball screw repairs are in high demand due to the critical role ball screws play in converting rotational motion to linear movement in CNC machinery, robotics, and automation systems. Precision repair, cleaning, lubrication, and component replacement are necessary to maintain efficiency, accuracy, and longevity.

Lathes—from multi-spindle and toolroom to CNC, turret, and grinding lathes—require periodic repair and refurbishment to deliver consistent shaping and cutting results. Machinery rebuilders provide expert lathe repair, spindle alignment, slideway grinding, and control retrofitting to keep these machines at peak performance.

History of Machinery Rebuilding

The roots of modern machinery rebuilding trace back to the United States during the 1920s and 1930s, coinciding with the rise of standardized industrial components. Initially, this practice involved the replacement of worn parts—like bearings and engine components—making equipment repair and engine rebuilding accessible and cost-effective. During the Great Depression, the economic necessity of extending the life of appliances, vehicles, and industrial machinery fueled the widespread adoption of rebuilding practices.

Henry Ford played a pivotal role by establishing the first American car engine rebuilding plant in 1932, which enabled automotive owners to remanufacture engines rather than purchase new vehicles. The importance of machinery rebuilding grew during World War II, when the U.S. government commissioned large-scale remanufacturing of ships, airplanes, tanks, and military vehicles—helping conserve scarce resources, expedite repairs, and maintain operational readiness.

Post-war, the machinery rebuilding industry continued to thrive, as businesses and consumers alike recognized the cost savings and resource efficiency of refurbishing equipment. The environmental movement of the 1970s added a new dimension, with growing awareness of energy conservation, sustainable manufacturing, and waste reduction. This led to increased demand for remanufactured goods and the integration of remanufacturing best practices into mainstream manufacturing.

In 1995, the U.S. Environmental Protection Agency’s (EPA) Comprehensive Procurement Guideline (CPG) program encouraged the use of recycled and recovered materials, further legitimizing machinery rebuilding and remanufacturing. The addition of rebuilt vehicle parts to the CPG in 2004 incentivized automakers to embrace sustainable rebuilding practices. Today, machinery rebuilding is a core strategy for companies seeking to lower costs, reduce their environmental impact, and comply with increasingly stringent regulations on waste and resource management.

Did you know? Many companies now rely on machinery rebuilding not only for cost savings but also to advance their sustainability initiatives and reduce their carbon footprint. Are you interested in learning how machinery rebuilding can support your environmental goals?

Service Details: What Do Machinery Rebuilding Companies Offer?

Machinery rebuilding services are structured, systematic processes that restore equipment to optimal or like-new condition. The typical workflow includes:

- Inspection and Assessment: Comprehensive evaluation of machinery condition, including wear analysis, failure diagnosis, and performance benchmarking.

- Disassembly: Careful breakdown of equipment to access components, with detailed documentation for accurate reassembly.

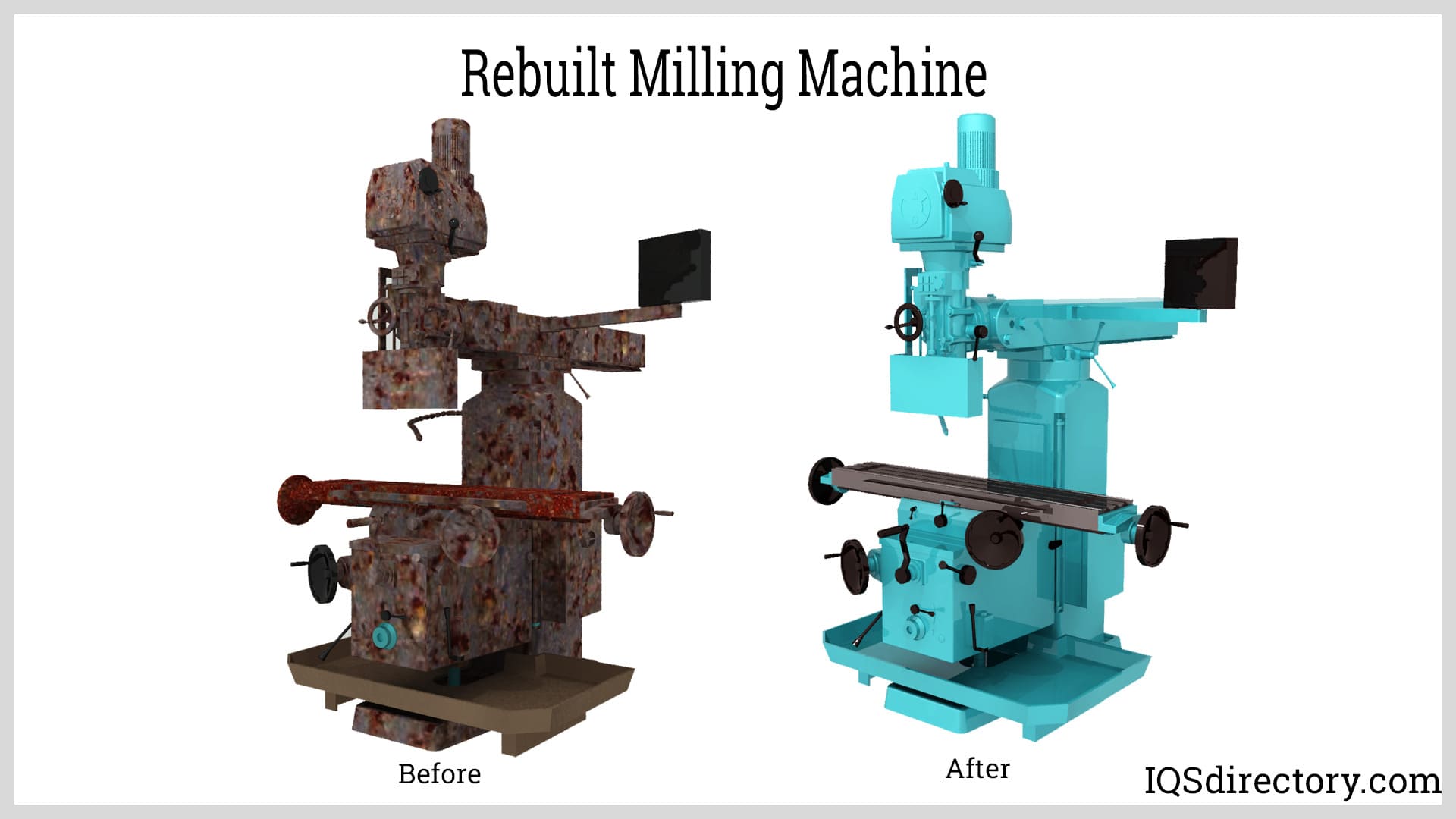

- Cleaning and Surface Preparation: Removal of contaminants, corrosion, and residues to facilitate precise repairs and upgrades.

- Component Replacement or Restoration: Damaged or worn parts are either replaced with OEM or aftermarket equivalents, or restored using advanced machining and material restoration techniques.

- Reassembly: Systematic reassembly using calibrated tools and adherence to factory specifications.

- Quality Testing and Performance Verification: Functional testing, dimensional checks, load testing, and system validation ensure the rebuilt machinery meets or exceeds original performance standards.

There are three core types of machinery rebuilding services:

- Repair Services: These address specific failures or malfunctions, typically by replacing defective parts or repairing damaged assemblies. While repair services offer a rapid, cost-effective solution, they may not resolve underlying wear or systemic issues.

- Rebuilding/Remanufacturing Services: This comprehensive approach involves full disassembly, restoration, and replacement at the module or system level. Remanufactured equipment is often upgraded with modern components, extends useful life, and includes warranties similar to new equipment.

- Retrofitting Services: Retrofitting involves integrating new technologies, automation controls, safety systems, or energy-efficient components into existing machinery. This extends the equipment’s capabilities and ensures compliance with the latest industry standards.

Curious about which type of service best fits your needs? Ask yourself: Are you looking for a quick fix, a complete overhaul, or future-proofing your equipment with advanced features?

Design and Customization: Tailoring Machinery Rebuilding to Your Needs

Before initiating repairs, rebuilds, or retrofits, machinery rebuilders conduct in-depth consultations to understand your operational goals, production requirements, and budget constraints. This enables them to design a customized rebuilding or remanufacturing plan that aligns with your strategic objectives and minimizes disruption to your workflow.

The design phase may include:

- Feasibility studies and cost-benefit analysis

- Reverse engineering obsolete or unsupported parts

- Material upgrades for improved durability or corrosion resistance

- Integration of digital controls, sensors, and automation

- Compliance review for safety, regulatory, and industry standards

Rebuilding teams may use various machining processes to achieve optimal results, such as demanufacturing for recycling, counterbalancing, retooling, material restoration, precision coating, surface polishing, painting, buffing, deep cleaning, and complete reconditioning. Modern rebuilders often provide digital documentation and traceability for parts and processes, which is valuable for audits and quality assurance.

Looking to upgrade your equipment for Industry 4.0? Many machinery rebuilding companies now offer retrofitting with IoT sensors, remote monitoring, and smart automation systems.

Machinery and Tools Used in Rebuilding

Throughout the machinery rebuilding process, technicians use a broad range of advanced machine tools and industrial equipment. This includes:

- Milling machines (manual and CNC)

- Precision grinders and surface finishing machines

- Injection and blow molding machines

- CNC screw machines and lathes

- Coordinate measuring machines (CMM)

- Heat treatment furnaces and surface hardening equipment

- Ultrasonic cleaning systems for contaminant removal

- Laser alignment and balancing tools

The use of computer numerical control (CNC) technology and advanced metrology ensures tight tolerances, repeatability, and the highest quality standards in every phase of the rebuilding or remanufacturing process.

Want to learn about the latest technologies in machinery rebuilding? Explore our guides on CNC retrofitting, smart manufacturing, and predictive maintenance.

Types, Variations, and Similar Processes

Machinery rebuilders classify their services based on the degree of restoration and the identity of the finished product:

- Rebuilding with No Loss of Identity: The machinery is thoroughly inspected, worn modules are repaired or replaced, and all defects are addressed. The equipment is returned to the customer with the same serial number and a warranty comparable to new equipment, ensuring a complete restoration of original performance and lifespan.

- Repetitive Rebuilding with No Loss of Identity: This process follows the same restoration as above but is performed on a regular, scheduled basis, often as part of a preventive maintenance program. It includes inventory management and process scheduling for high-volume or mission-critical applications.

- Rebuilding with Loss of Original Product Identity: Used machinery is disassembled, and its components are refurbished and sorted into inventory pools. These parts are then reassembled into fully remanufactured products, which may carry a new identity or part number. This approach is common in the automotive and heavy equipment sectors.

Related processes include remanufacturing, refurbishment, retrofitting, and preventive maintenance. Each has unique advantages based on the equipment type, operational goals, and regulatory environment.

Benefits of Machinery Rebuilding and Remanufacturing

Investing in machinery rebuilding offers a wide range of benefits for businesses of all sizes:

- Cost Savings: Rebuilding and remanufacturing are often significantly less expensive than purchasing new equipment, freeing up capital for other investments.

- Reduced Downtime: Fast turnaround and expert diagnosis minimize operational interruptions, keeping your production line running smoothly.

- Enhanced Performance and Reliability: Restored equipment is tested to meet or exceed OEM performance standards, ensuring consistent output and product quality.

- Environmental Sustainability: Machinery rebuilding conserves raw materials, reduces landfill waste, and lowers the carbon footprint associated with new manufacturing.

- Regulatory Compliance: Upgrading or retrofitting older equipment can help you meet current safety, emissions, and industry-specific regulations.

- Customization and Modernization: Tailored upgrades, automation, and digital controls can give legacy equipment new capabilities and extended value.

From gaming consoles and HVAC units to bakery machinery, engines, hydraulic systems, and high-precision industrial robots, virtually any piece of equipment can benefit from rebuilding and remanufacturing services.

Are you comparing the costs and benefits of equipment repair versus replacement? Our in-depth comparison guides can help you make an informed decision.

Buyer’s Guide: How to Choose the Right Machinery Rebuilding Company

Selecting the best machinery rebuilding company or remanufacturing partner is a critical business decision that can impact your operational efficiency and equipment ROI. To help you make a confident choice, consider the following steps:

- Define Your Requirements: Start by documenting your application specifications, including machine types, production goals, quality standards, budget, and delivery deadlines.

- Research Service Providers: Use industry directories, online reviews, and referrals to create a shortlist of experienced machinery rebuilders with proven track records in your industry.

- Compare Capabilities: Evaluate each company’s expertise in your specific equipment category (e.g., CNC machines, presses, pumps), their use of advanced technologies, and their approach to quality assurance.

- Assess Customer Support: Reach out to potential partners to gauge their responsiveness, technical knowledge, and willingness to answer your questions. Excellent customer service is a key indicator of reliability.

- Review Quotes and Turnaround Times: Request detailed quotes and timelines for your project. Compare offerings to ensure you’re getting a fair price, realistic delivery, and comprehensive warranties.

- Check References and Certifications: Verify the company’s certifications (such as ISO 9001, AS9100, or OEM approvals) and speak with past clients to ensure consistent quality and satisfaction.

Once you’ve narrowed your list to a few top contenders, ask for case studies, references, or site visits to further validate their expertise and capabilities. Make your final selection based on technical fit, service quality, and overall value.

Ready to get started? Browse our list of trusted machinery rebuilding companies and request a quote today.

Frequently Asked Questions about Machinery Rebuilding

- What is the difference between repair, rebuilding, and remanufacturing?

Repair addresses specific faults; rebuilding restores overall function and appearance; remanufacturing upgrades and modernizes equipment to like-new or better standards. - How long does machinery rebuilding take?

Timeframes vary by equipment type, service complexity, and parts availability. Most projects can be completed within weeks, while extensive remanufacturing may take longer. - Is machinery rebuilding cost-effective for all equipment?

Generally, yes—especially for high-value or specialized machinery. A professional assessment will determine if rebuilding offers better ROI than replacement. - What warranties are available?

Many machinery rebuilding companies offer warranties comparable to new equipment, covering both parts and labor. - Can I upgrade my existing equipment with automation or smart controls?

Yes! Retrofitting is a popular service that integrates modern automation, digital controls, and IoT connectivity into legacy machinery.

Still have questions? Contact our team or consult our machinery rebuilding experts for personalized advice.

Conclusion: The Value of Machinery Rebuilding for Modern Industry

Machinery rebuilding and remanufacturing are essential strategies for maximizing equipment value, improving operational efficiency, and achieving sustainability goals. By partnering with experienced machinery rebuilders, companies can extend the life of capital assets, reduce costs, and stay competitive in an evolving industrial landscape. Whether your focus is cost savings, environmental stewardship, regulatory compliance, or technological advancement, machinery rebuilding delivers measurable benefits across a wide spectrum of industries and applications.

Explore our comprehensive directory of leading machinery rebuilding companies to find the right partner for your next equipment repair, remanufacturing, or retrofitting project. Ready to boost productivity and sustainability with expert machinery rebuilding? Start your search today.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services