The term “machinery rebuilders” is a label that has been largely replaced by the now-common “remanufacturer.” Both terms, however, are valid. They refer to service companies that replace and/or take apart, clean, and repair different machines and machine parts. The goal of machinery rebuilders is to increase equipment life and, occasionally, provide preventative maintenance. Read More…

If you need to get your critical system back up and running again as quickly as possible, Precision Service Machine Tool Rebuilders, Inc. has what you need. Since 1983, Precision Service MTR has been a reliable and trusted resource in the field of industrial machinery repair. Our highly skilled service technicians offer custom rebuilding strategies, onsite repair, and unmatched service.

At Lindquist Machine Corporation, we take pride in our role as machinery rebuilders, dedicated to providing exceptional solutions to our valued clientele. With a rich history of expertise and dedication to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner in the industry. Our core focus lies in rebuilding a wide range of machinery, including CNC...

We are machinery rebuilders specializing in press rebuilding and repair plus clutch rebuilding and conversion. Our machine shop repairmen average 25 to 35 years of experience with all types of metalforming and manufacturing equipment. We can provide on-site service including new part fabrication.

At Betar, Inc., we pride ourselves on being expert machinery rebuilders, dedicated to providing top-tier solutions to our valued clientele. With a wealth of industry experience and a steadfast commitment to quality, innovation, and customer satisfaction, we have cemented our reputation as a trusted partner in the realm of machinery repair and refurbishment. Our primary focus revolves around the...

Welcome to Benning, where we specialize in rebuilding, repair, retrofitting, hand scraping and service on all types of precision metal working equipment. We provide services at our place or yours and machine size is never a factor. Some of the services available are spindle grinding, way surface repair, complete leveling service and much more. We’ve been servicing machine tools since 1972.

More Machinery Rebuilding Companies

Machinery rebuilders typically operate out of machine shops, where they have access to a vast array of tools and equipment necessary for their work. They offer a wide range of services related to equipment repair and the rebuilding of machinery and machine tools.

These professionals service components and products used across various industries, including automotive, computer electronics, photography, industrial manufacturing, textiles, green energy, and printing.

Machinery rebuilders handle everything from heavy equipment to small electronic parts. They are skilled in repairing, reworking, and overhauling a diverse range of components, products, machines, and machine tools.

In the industrial manufacturing sector, for example, machine rebuilders frequently repair and rebuild items such as presses, pumps, and tools. They also occasionally work on gearboxes, spindles, ball screws, and lathes.

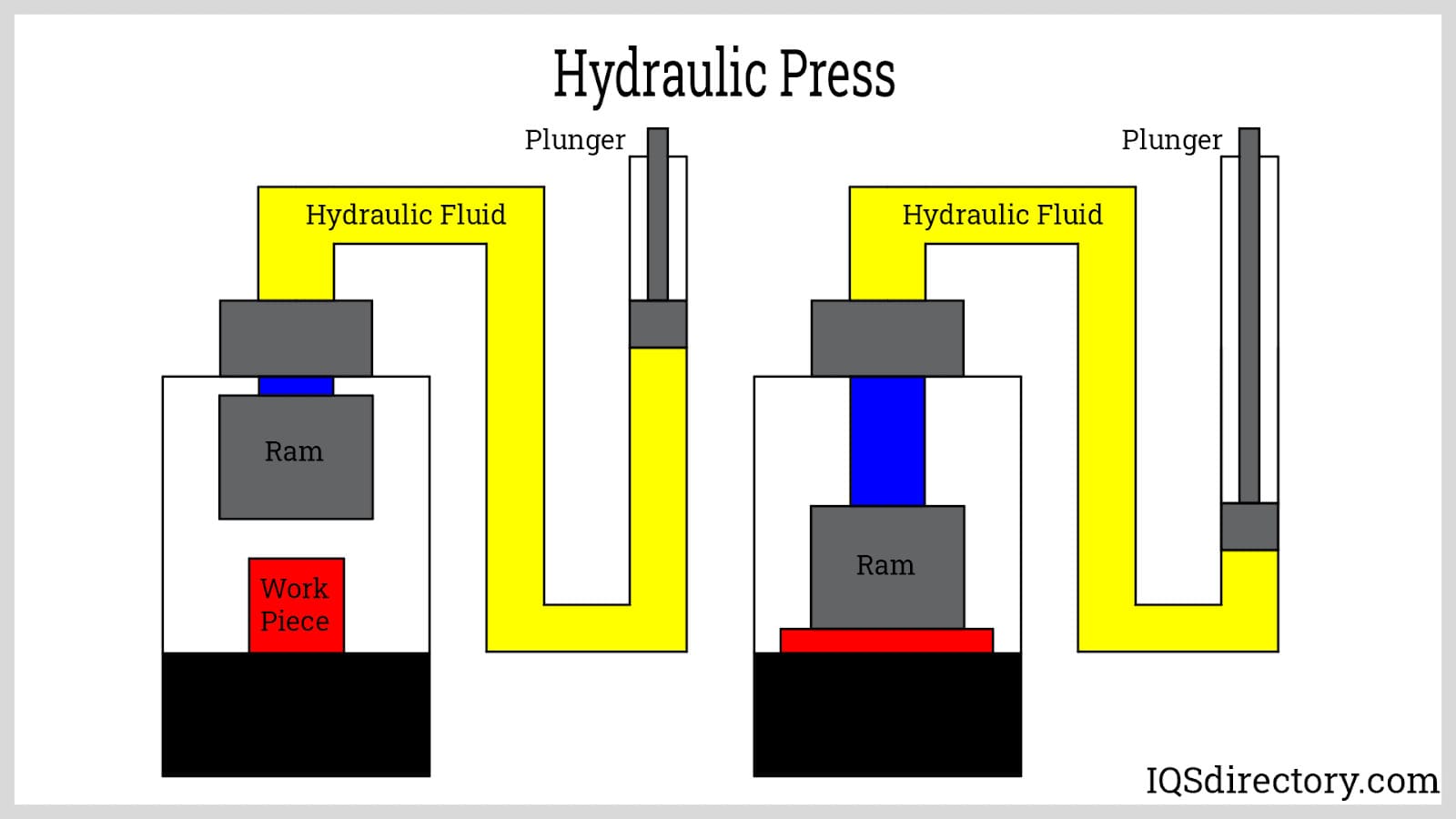

Machinery rebuilders service a variety of equipment and industrial machinery used to apply force or pressure to materials. This includes several types of industrial presses such as C presses, hydraulic presses, mechanical presses, printing presses, and stamping presses, all of which often require press repair.

b>Pump repair services encompass a wide range of pump types, including centrifugal, hydraulic, metering, and vacuum pumps. Any device or machine designed to transfer, compress, or lift fluids falls under this category and is eligible for repair services.

Tool repair, machine tool repair, and rebuild services cover devices used for both mechanical and manual tasks. This includes a broad array of tools from pressure sensors to power machine tools.

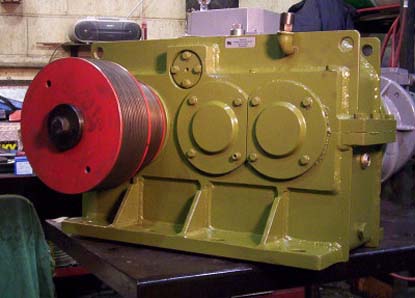

Gearboxes, which protect gear systems, are essential in various industries including aerospace, automotive, and manufacturing. Due to the numerous gearbox styles such as spur, helical, and planetary, gearbox repair services are diverse and extensive.

Spindles, used to spin and twist fibers into yarn, are typically equipped with features like hooks or grooves. Although spindle repair and rebuilding are less common, they play a crucial role in the textile industry.

Ball screw repairs are highly sought after since ball screws, which convert rotational movement into linear motion, require meticulous maintenance to ensure optimal performance.

Lathes, which shape materials through rotation and various cutting tools, benefit from repair services to maintain their functionality. Machinery rebuilders can service multiple types of lathes, including multi-spindle, toolroom, CNC, turret, and grinding lathes.

History

The concept of modern machinery rebuilding originated in the United States during the 1920s and 1930s. This practice gained traction as standardization allowed for the replacement of parts such as bearings, engine repairs, and refurbished products. During the Great Depression, machinery rebuilding proved to be a cost-effective solution for those unable to afford new appliances or cars. It provided an affordable alternative to purchasing new products or going without.

In response to this trend, Henry Ford established the first American car engine rebuilding plant in 1932. During World War II, the U.S. government furthered the practice by commissioning the remanufacturing of ships, airplanes, and military vehicles like tanks. Even after the war and economic recovery, the appeal of machinery rebuilding persisted as a practical and economical choice.

The 1970s brought a new dimension to machinery rebuilding with the rise of environmental awareness. As people became more conscious of their carbon footprint and the environmental impact of their actions, the demand for remanufactured goods surged. This shift towards sustainability led more manufacturers to seek out machinery rebuilding services, which helped conserve resources and reduce energy consumption.

The industry’s growth continued through the latter half of the 20th century. In 1995, the EPA’s Comprehensive Procurement Guideline (CPG) program encouraged manufacturers to use recycled and recovered materials, further boosting the demand for machinery rebuilding services. The addition of rebuilt vehicular parts to the CPG list in 2004 provided an additional incentive for automotive manufacturers to invest in rebuilding services.

Today, with environmentalism and waste reduction at the forefront of consumer concerns, the machinery rebuilding industry is thriving. As regulations on resource use and disposal become more stringent, this trend is expected to continue well into the future.

Service Details

Machinery rebuilding services generally follow a sequence of inspection, disassembly, cleaning, replacement or restoration, reassembly, and quality testing.

There are three primary types of rebuilding offered:

- Repair services: This involves fixing a machine by replacing faulty parts or reassembling damaged components. Repair is typically a short-term solution and does not address the machine’s long-term needs.

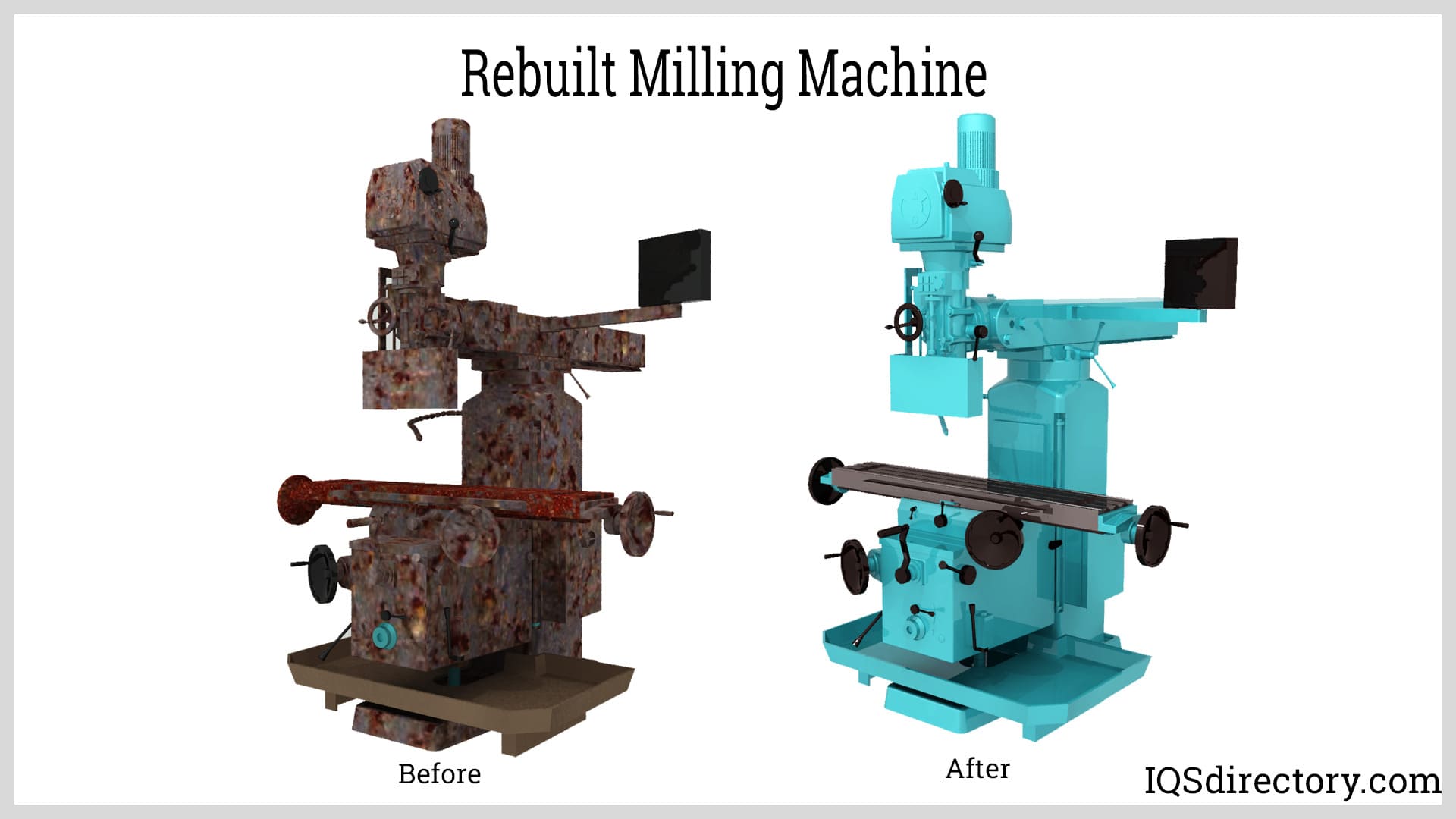

- Rebuilding/remanufacturing services: This process provides a more thorough transformation of the equipment. It includes disassembling the machine, recovering it at the module level, and restoring it to its original condition. Remanufactured machines often deliver performance and longevity comparable to new ones due to the high standard of restoration.

- Retrofitting: This service updates equipment by adding new devices, components, or technologies that were unavailable or uncommon at the time of the machine’s original manufacture.

Design

Before embarking on repairs, rebuilds, or retrofits of machinery, rebuilders must carefully review several key factors. Initially, they need to understand the customer’s objectives. Following this, they must devise a plan to achieve these goals while staying within the customer’s budget.

Based on these considerations, the rebuilding team will outline a comprehensive plan from start to finish. This may involve a range of machining processes to restore the machinery to a like-new condition. Examples of these processes include demanufacturing (disassembling parts for recycling), replacing parts, counterbalancing, retooling and reorienting parts, material restoration and strengthening (such as coating, polishing, painting, buffing, and reconditioning), deep cleaning, and more.

Machinery Used

Throughout the rebuilding process, service providers utilize various machine tools and equipment, including milling machines, CNC machines, injection molding machines, grinders, blow molding machines, and CNC screw machines.

Variations and Similar Processes

Machinery rebuilders categorize their services into three main types: rebuilding with no loss of identity, repetitive rebuilding with no loss of identity, and rebuilding with loss of the original product identity.

Rebuilding without identity loss involves a thorough inspection of the machine’s body for integrity, updating, overhauling, or replacing its modules, fixing any defects, and returning the equipment to the customer in a condition comparable to new. This means the machine will have the same expected lifespan and warranty as a brand-new unit.

Repetitive rebuilding without identity loss follows a similar process but includes additional steps such as scheduling dependent processes and managing inventory buffers. This method is close to a full overhaul but doesn’t quite reach that level.

Rebuilding with the loss of the original product identity entails disassembling used machines, refurbishing their parts, and organizing these parts into inventory groups. These groups are then reassembled into a remanufactured product.

Benefits

Machinery rebuilders play a crucial role with numerous benefits. By repairing and refurbishing machines, they not only help businesses cut costs but also contribute to environmental sustainability by reusing and recycling resources. This process enhances equipment efficiency and extends its lifespan.

Furthermore, remanufacturing supports the affordability and performance of a wide range of equipment, from gaming consoles and air conditioning units to bakery machinery, engines, and hydraulic systems.

Things to Consider

Machinery rebuilders offer invaluable services, providing you with the opportunity to extend the lifespan of your machinery. With the right contract manufacturer, you can ensure many more years of efficient operation. However, with the wrong one, you risk a malfunctioning system and financial losses. To empower you in finding a trustworthy machinery rebuilding company, we have compiled a list of the most reliable ones. Explore the profiles of these equipment rebuilders by scrolling up.

Before you scroll up, though, we suggest you take the time, if you have not done so already, to write down your application specifications. Don’t forget to write down your standard requirements, your budget, your delivery preferences, and your delivery deadline. Once you have done that, start browsing. You can quickly eliminate some contenders by comparing their offered services to the ones you have written on your list. Eliminate more until you’ve got three or four top picks.

From here, give each of them a call or send quote request. Make sure you get all the answers you need from each of them. If a customer service representative is not patient or does not want to answer your questions, pass on them. A considerate staff is one of the most important features of any supplier, no matter the industry. Once you have spoken with each potential service supplier, compare and contrast their quotes, and pick the supplier you believe will best serve you.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services